- Company

-

- Solutions

-

- Technology

-

Magnetic Precision: Where Current Becomes Culinary Art.

Resistive Excellence: Uncompromised Heat for Every Vessel.

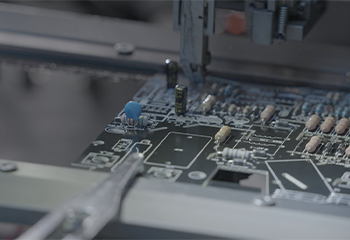

Precision Heating Systems for Demanding Environments.

Ultra-Low 0.1s Latency for Instant Response.

-

- News

-

- Contact